Our expertise

Lava enamelling

A centuries-old skill

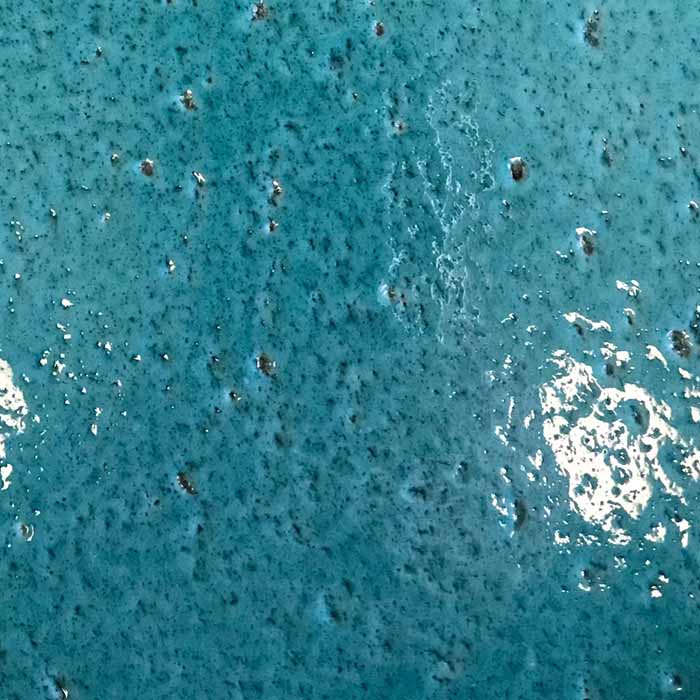

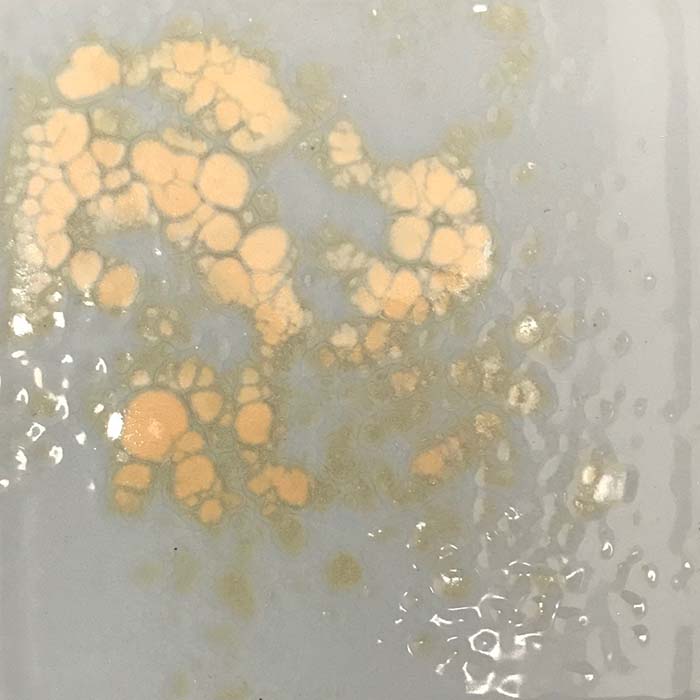

The lava enameller practices enamelling, a technique which allows a support to be covered with a vitreous layer; pigments are fixed to the support by firing at a temperature close to 960°C. Lava is the only type of stone that can be enamelled.

This ancestral savoir-faire, several centuries old, is now recognised as an art form, halfway between the art of stonework and the art of fire. Behind the rigour and meticulousness that enamelling on lava imposes, the secret of this craft is undoubtedly “passion”.

The achievements of many lava enamellers have spanned the centuries. From the unique to the spectacular, each of them tells us a part of history, leaving us stunned by their preserved beauty.

Enamelled lava

Sélectioning

It all begins with a sketch, a plan, a schema to be carried out.

The journey continues in one of the quarries at the foot of our Auvergne volcanoes.

Each lava flow has its own colour, texture and porosity.

The flows of the Puy de la Nugère gave birth to the Volvic lava, those of the Puy de Sancy to the Mont Dore lava and the Puy de Dôme and Côme to the Chambois lava.

All these lava flows, although different, offer the same technical characteristics that all lava stone has; the main ones being the high resistance to thermal, meteorological and atmospheric variations.

After selecting the type of lava suitable for the project, blocks are extracted and then transported to the workshop at the foot of the Puy de Dôme, to begin shaping, machining and sculpting.

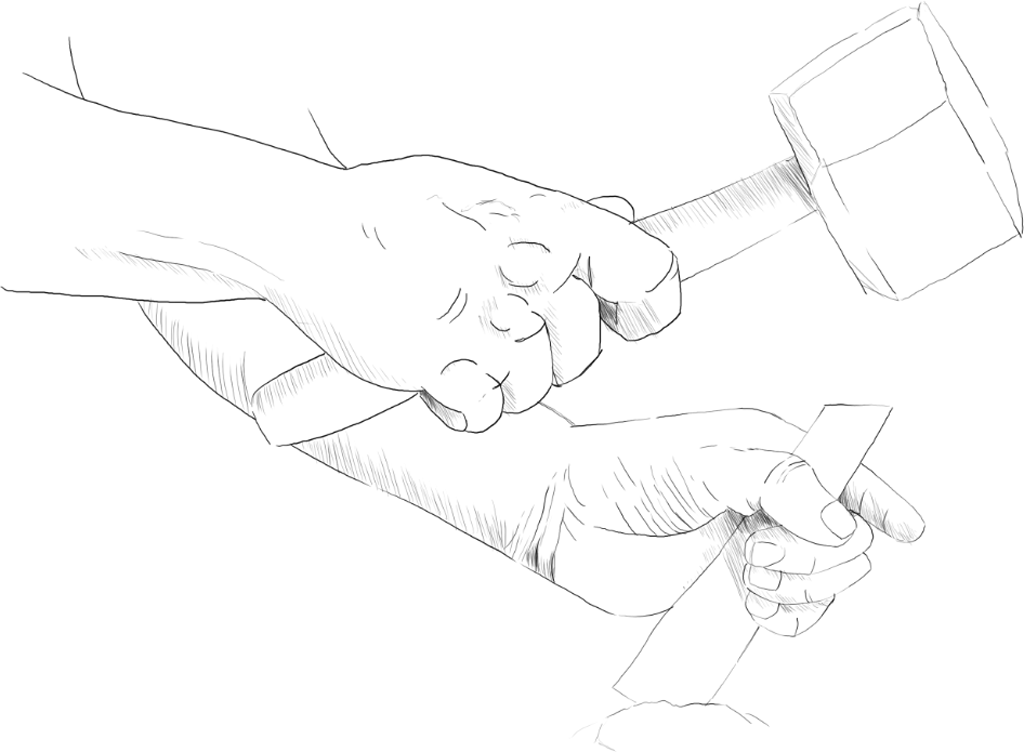

Sculpting

The lava arrives in blocks.

After a first preliminary cutting with wire, slices are cut according to the thickness required for the project.

The stone is then shaped until the desired piece is produced. The shaping can be done by NC (numerical control) or manually, depending on the complexity of the piece.

The combination of machines and human hands allows us to produce pieces of great precision, with fine finishes, where artisanal methods make the real difference.

Enamelling

With the stone shaped; work on the lava can begin…

*Preparing the stone of enamelling – After meticulous washing, a drying period is required. Then the slip is applied to the entire surface to be enamelled (this is necessary for a perfectly smooth and uniform glazing.) Again, a drying period is necessary.

*Firing[phase 1] – time can vary between 6 to 12 hours depending on the pieces to be fired. Solid piece, specific glazing etc…

*Enamelling the lava – after careful preparation of the colour, it is time to use the gun, the cruet and the brush! This is a technique that is mastered over the course of many projects and years.

*Firing [phase 2] – once again a firing is necessary to fuse the enamel and the lava. Firing times can vary, as can the temperature curves.

*Quality control – after each firing, the pieces are examined to check the quality of the finished piece. If necessary, additional glazing and firing is carried out to rectify any imperfections.

in summary

A volcanic project is

An eruption of ideas

A flow of lava

An eruption of enamel

An intense fusion

An unique achievement

Top of the range creations

Combining artisanal know-how, natural materials, high technicality, sensitivity to the smallest detail… Our creations have earned their place in the high end market.

tradition pierre :

reactivity adaptability professionalism savoir-faire passion

Lava stone

Noble and natural

Enamelled lava

Technical advantages

The works

Personalised et unique

The creations

French and made to measure

Enamelling

Ancestral and artisanal

Technical expertise

Methodology

and know-how

Enamels

Quality and certified

finishings

Soignées, meticulous

our projects